Our idea

Our idea is to enhance Google Glass battery life with a single push

of a button. GAZERglass is a battery pack that extends your Google Glass

power almost three times more than its original capacity.

![]()

What We Need & What You Get

We plan to attach Lithium-Polymer battery

with the capacity of approximately 1500mAh to the

left side of the Glass. It will be inserted into a plastic case with micro-USB output which will be used for re-charging;

there will be an LED light indicating state

of the battery charge and a button to start/stop charging.

![]()

Nicely braided cord will be coming out of the battery along with thin plastic

holders preventing breakage of the cord. On the

other side of the Glass you will connect to micro-USB input and leave it like

that forever, because you will be able to transfer data through the GAZERglass

battery as well as to charge your device. Thanks to the neat cord behind your

neck - you will be able to take your glass off and keep them hanging on you when you don't use them

![]()

We have tested few batteries from different manufacturers and have chosen one

we like the most. Circuit board protection for the battery was customized for

our needs and we have schematic design and sample ready as well. Plastic case was printed

on 3D printer, and we have internal and external model structure with sizes

ready for production. The most expensive part of production will be making a

mold for our plastic case. The second part is to

make a mold for Li-Po battery. Third -

production and packaging. When you open a package you will get a fully

operational battery designed for use with

Google Glass.

![]()

You can also use it to charge

any mobile device that consumes about 5V & 0.5A (iPhone and Android).

Stretch goals

Our company was approved for a bank loan, but we are

still somewhat short on funds. We are thankful to everyone who supports

us.

![]()

Our story

Andrey is a GAZERglass idea creator. While we were working on Google

Glass software he noticed that Glass’ battery life is too short to

handle many activities that are offered to users. So Andrey had an idea

to extend battery life, creating GAZERglass in his mind as a potentially

great project.

![]()

Anton is Andrey’s friend, partner and co-founder of Worldintercom, Inc.

He is working on GAZERglass project to make it attractive to the end

user. Convenient, affordable, and perfect product is the main goal that Anton

set for our team. His idea is to make GAZERglass a unique piece of art,

that is harmoniously combined with Google Glass.

![]()

We also have Guli and Timur in our team. Guli is our General Manager responsible for customer service and public

relations. She is ready to professionally assist anyone with any questions

related to our products and services. Timur has genius skills in Search Engine Optimization, Internet

Marketing, Social Media Advertisement, everything to organize successful

promotion of our services and products to the IT market. He is the guy

who will be posting news and updates about GAZERglass project on our

website.

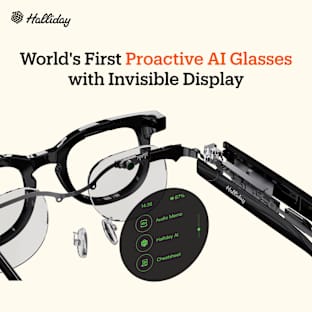

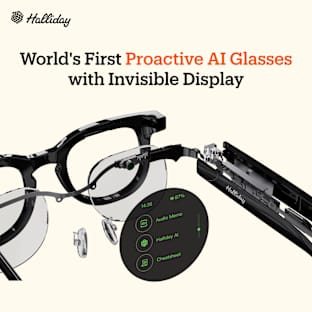

Design

In Moscow we worked together with the team of professional

designers SMIRNOVDESIGN. Their view of a future product combined with a subject expertise produced beautiful GAZERglass battery concept.

We started with plasticine

model and drew a few sketches,

![]()

then we worked on 3D model of a final object,

![]()

and finally 3D printed our first working prototype which you could also see on the video.

![]()

You are welcome to meet our designer team also.

Sergey is a president and founder of “SmirnovDesign”, company based in

Moscow, which works on GAZERglass project design and architecture.

His

company is one of the leaders in an industrial design, cooperating

together with Skolkovo Innovation Center.

![]()

Kirill and Ivan are the other team members who put a lot of efforts

into the GAZERglass project. Kirill is

responsible for styling, modeling and end product visualization; his

ability to concentrate on task and get the job done leaves no doubts

about success of any complicated idea that we might have. Ivan is a

young talented designer and his responsibilities include general product

concept,

ergonomics, and composition. Ivan is very passionate about his projects

and does the best for every project he works on.

Go green with GAZERglass

We are concerned about our

environment and truly support an idea of plastic waste reduction. Our

designers and engineers developed a very thin GAZERglass battery case to

reduce plastic consumption.

Less plastic = more green!

![]()

Technical data & facts

Forecasted specs:

1500mAh Lithium-Polymer Battery Pack.

Simultaneous charging and data exchange via micro-USB

Lightweight and compact design. Convenient charging cable.

Only 3.5 ounces (100 grams)

Next steps

![]()

Here is some more information:

1. Our first step was to make 3D prototype of our design model.

That was accomplished back in September. We printed plastic case using 3D printer

in Moscow; then we bought a USB cable and attached it to our prototype. At the same time, Andrey was searching for a Li-Po battery manufacturers in China, and ordered samples from 3 companies.

2. We received samples when we came back to New York in October and this is when our next challenge begun.

We had to test those sample batteries in order to find out which one works better, holds more power, and doesn't get too hot during work process. After we were done with tests, we inserted battery inside the plastic case, soldered all wires, and finally got everything that we need to charge Google Glass. This is when our functional prototype was born.

3. Currently we are looking for ways to fund our project.

We thought it might be a great experience to try Indiegogo as a way to raise funds. But we have also applied for a business loan and were approved. Surely we would prefer Indiegogo project to do well rather than using bank's money to avoid paying interest and endless fees.

4. Our next step will start when we go to China in 2014 (around 18-19th of January) to start manufacturing process.

We want to be on top of this process and stay in China (Shenzhen) for about 6 weeks in order to control quality of production. This is what is going to happen there:

a) creation of molds for battery itself and it's plastic case. This is done with the same manufacturer.

It will take 1 week. Approximate dates: January 20th-26thb) production of battery and plastic case. Assembling all of them together with USB cable and other plastic parts. Testing process.

It will take 4 weeks. Approximate dates: January 27th - February 24thc) production of battery package. This is done with another manufacturer in China.

It will take 2 weeks. Approximate dates: February 10th - February 24thd) we will pack everything together. Ready to ship!

It will take 1 week. Approximate dates: February 24th - March 2nd5. Final step is to deliver GAZERglass to the United States. Shipping by air and going through the customs won't take longer than a week, so we expect to have everything in our warehouse by March 9th. As soon as we get it, we will start sending battery packs to our early birds. After GAZERglass opening ceremony (around 20th of March) we will continue to ship batteries and will start regular sales in April.

Risks and challenges

Our team is experienced in design, development, production and

logistics of an end product. Our company is running for 2 years

already, during which we successfully developed several hardware and

software projects.

Of course there are always possibilities to be delayed at some point

or to have an unforeseen expense, but we are bringing our experiences

together with our partners and making a unique alliance which will prove

itself. If any problems come up during the production cycle we will

solve them using our own funds and resources. We will do our best to

deliver GAZERglass on time.

Things you might be concerned about:

Design: our partners from Moscow, Russia created a beautiful and

unique design of GAZERglass battery, so we have successfully overcame

this challenge.

Prototype: 3D modeling and engineering of GAZERglass as a final

product was a successfully completed task that ended with our real

functioning prototype.

Product parts: we have tested few batteries from different

manufacturers and have chosen one we like the most. Circuit board

protection for the battery was customized for our needs.

Production: agreements were made with manufacturers and we are ready to start GAZERglass battery production.