Jul Bujh is a snap on retrofit device that improves the efficiency of millions of legacy water heaters across the globe, making them eco-friendly

![]()

![]()

![]()

![]()

![]()

Installation videos will be available for download through our web site close to shipment date of the product.

![]()

![]()

The Apps will be available for download from respective official App stores for iPhone and Android platforms at the time of product shipment.

![]()

![]()

All Jul Bujh devices in all packages can be shipped to different addresses all over the world. All devices can also be donated for install at a not for profit facility. We can install on your behalf at a location of your choice in Pakistan or we can select one for you if you like.

![]()

In the winter of 2012, Zia Imran and his friend Farrukh Kamran, struck up a conversation on how the natural gas bills were going through the roof during winter months and what could be done to reduce them. They figured that a large portion of a utility bill is because of inefficient household appliances especially the water heater. This is because the legacy thermostat's design is static and time independent: once you set the thermostat at a particular level, the water heater only maintains the water at that specific temperature, regardless of whether you are using hot water or not. Throughout a cold night, when no one is using water, the water heater continuously burns gas to heat water. This wastes the individual’s money, wastes the world’s energy resources and pollutes our atmospheres. Zia and Farrukh figured there must be an elegant way to make this thermostat intelligent and the water heater economical and eco-friendly. This is what they cooked up on a napkin by the end of the conversation.

![]()

![]()

![]()

One cold morning, Zia noticed this public information AD in the newspaper.

![]()

This advertisement by the gas distribution company asks people to turn their thermostats to hot before they need warm water and then turn it off when they are done. How many people will get up at 5 in the morning to turn on the heater for when they need a shower at 5:30? Not many. And this is ignoring the discomfort of going outside in sub zero weather.

This impractical suggestion motivated us more to do something about the energy problem.

![]()

![]()

![]()

By winter of 2013, we had designed various product prototypes. We settled on a design close to our final production design shown below. We built 25 units laboriously by hand. 20 of these were deployed in the field and the response was awesome. In two days, our Facebook post resulted in a few hundred requests to get the device. Our users have been very happy and based on some of the feedback received, we have modified the hardware and software design, some details of which are provided below.

![]()

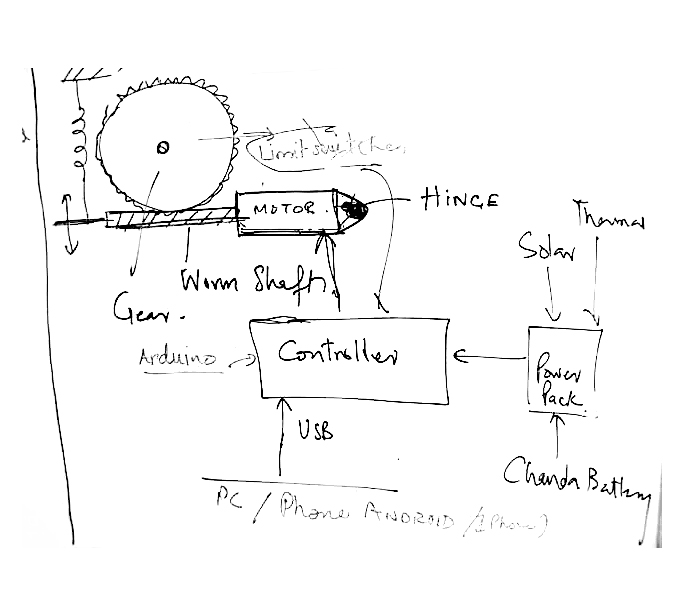

Our hardware design is so efficient and uses so little energy that Jul Bujh can operate one full winter season without battery replacement. In fact the two AA cells that power the processor circuitry can last up to a year and a half, whilst the other two AA cells powering the motor will last full winter season. The hardware configuration has 3 main components: a motor, two optical sensors and a microcontroller. The motor rotates a shaft which is coupled with the “key” on the thermostat. The time for which the motor rotates is determined by feedback from the optical sensors and the microcontroller. The chip used is Texas Instruments’ CC2540. This chip can then communicate with your Bluetooth Smart mobile phone through BLE (Bluetooth Low Energy). Thus, the user tells the chip what to do through an App and, using feedback from optical sensors, the chips turns the motor on and off, hence rotating the thermostat key at the right time. Here is the assembly diagram, cross-section and circuit for Jul Bujh.

![]()

![]()

![]()

We care about how the product is packaged and shipped. Here is a concept design of our packaging. Although it doesn't have our branding yet but you can appreciate the care with which your Jul Bujh will be packaged and shipped. The packaging container would be so nice that we are sure you would like to keep it around!

![]()

![]()

We have already built an Android App that connects with Jul Bujh wirelessly through BLE (Bluetooth Low Energy) to program it and fetch battery status and diagnostic information. An iPhone app is in the works. The embedded software in the TI Chip has the capability to detect malfunctions of the motor drive. If the motor gets stuck for some reason the status is recorded and reported back to the user's phone when it comes in range (BLE has a line of sight range of 80 feet). The embedded software also keeps an eye on battery levels and reports low battery status to the phone so user can replace batteries.

![]()

![]()

We have put together a team of seasoned industry veterans and young engineers. We need your pledges to support a greener earth, reduce pollution, lower greenhouse gas emissions while saving households money that they are wasting today.

We need to get to volumes that justify investment in building dies and molds for mid to large scale production. We can only build a small number of units by hand. The process needs to be automated and that takes investment in working with vendors to setup production lines. We also need to make minimum purchase commitment for electronic parts and assembly to keep cost of the unit realistic.

People say hardware is hard to do but we have assembled a great team, proven our concept in the field and demonstrated the value of our solution. The product pays for itself in less than four months. This ROI cannot be beat.

![]()

If you take the case of Pakistan, a typical developing country, an average monthly gas bill is $70 for one geyser turned on to max for the full month. Using Jul Bujh, a person can typically achieve $20 in savings at the minimum. If you total that over at least 5 million households* across the nation, you obtain savings of at least $100 million every month.

And that is just the monetary returns. There are the obvious environment benefits: fewer fossil fuels burnt means less carbon dioxide, fewer ozone damaging gases and decreased particulates in the air. Furthermore, decreased consumption of natural gas means the nation’s energy reserves sustain for a longer time. Cost of 1 unit of gas will stabilize as danger of overconsumption passes. This means that the underprivileged will not be priced out of natural gas.

![]()

![]()

![]()

We say thank you to following individuals and institutions for their contributions to this project. Without their support at critical junctures, Jul Bujh would would not have been where it is today.

Professor Belal Hashmi at FAST National University Lahore - affectionately known as Baoo Ji by his students for his selfless devotion to his student and teaching - for helping us debug our hardware.

Dr Umar Suleman at FAST National University Lahore - for helping us with embedded software just when we thought we had hit a roadblock.

Usman Younas of Arbisoft who helped us put together the video for gratis. He spent countless hours with us novices patiently putting up with missed dialogs and retakes.

Steve Moore for providing guidance over and above for what he signed up for.

Ashar Nisar for helping put together the Indiegogo page. He has always been there as a friend and facilitator in many of my foolish and not so foolish endeavors. I value your help and friendship a lot.

Anser Hussain Siddiqui for your input on our campaign page and acting as a bouncing board for ideas. Thanks for being part of the project, you have been a great help.

CASE - Center for Advanced Studies in Engineering, Islamabad for letting us use their labs for our hardware debugging.

and most importantly Babar Ahmad (Mindstorm Studios) and Jehan Ara (PASHA) for their material support and encouragement - It just would not have been possible without them. Thank you from the bottom of our hearts.

Risks & Challenges

Let's face it, hardware is difficult to do. Especially hardware which involves multiple technologies like Jul Bujh does. Jul Bujh needs three distinct set of expertise, software, hardware design and mechanical and industrial design. We have tried reducing the risk for Indiegogo community by not only developing a prototype but producing and installing 20 units last winter in the field to learn from our customers.

Based on this feedback we have altered the design a bit, added more software features and moved the process form a hand made approach to a mass production process. This conversion to larger scale production and debugging the final design is going on right now. We are very confident that given the experience of the team and our ability to build 20 units and install them successfully in the field will enable us to automate production of larger batches of units by first week of November so we are ready for production runs by end of November.